Lecture Hall HCI J6, 16:30

Dr. Jürgen Schawe

Laboratory of Metal Physics, ETH Zürich

Calorimetry on Atomic and Molecular Systems in the Millisecond Scale

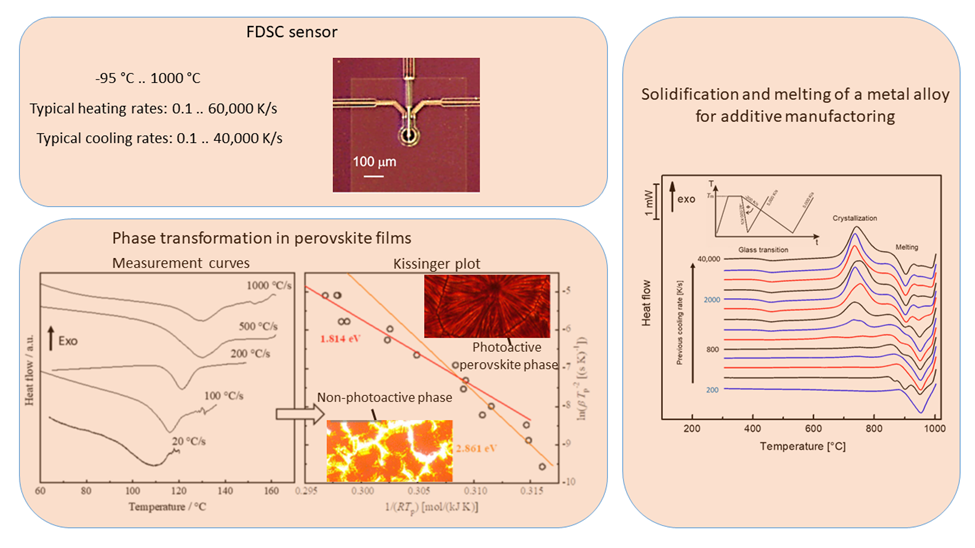

Conventional differential scanning calorimetry (DSC) is a standard technique for analyzing compounds and materials. It is a relatively fast, sensitive and easy-to-use method for detecting the occurrence of phase transformations and chemical reactions and for determining their kinetics. The limits of this technique are defined by the relatively large signal time constant of several seconds and the maximum heating and cooling rates of about 100 K/min (1.7 K/s). In contrast, the cooling rates in technical solidification processes are generally at least 2 to 4 orders of magnitude higher. This was the motivation for the development of non-adiabatic MEMS chip-based fast DSC (FDSC) with heating and cooling rates of up to several tens of thousands of K/s and time constants in the millisecond range.

The FDSC technique opens a new window for kinetic investigations, the possibility of thermodynamic characterization of unstable phases, polymers and organic compounds, but also the measurement of small samples such as thin films and complex composites as well as advanced hybrid materials. Furthermore, it is possible to use this technique to correlate in-situ and ex-situ measurements with structural characterization techniques such as electron microscopy and micro- or nanofocus X-ray diffraction.

Prof. Dorina Opris

Laboratory of Functional Polymers, EMPA

Navigating the Challenges and Exploring the Potential of High-Permittivity Dielectric Elastomers

Polymers with high and finely tunable dielectric permittivity are of great scientific interest because of their wide range of potential applications, from transducers and capacitors to lithium-ion batteries. But how much can the permittivity be increased, and how does this increase affect other properties? To answer these questions, we have modified the polysiloxanes with different types and amounts of polar groups and investigated how these chemical modifications affect different properties. We are also investigating the effect of filler addition on the properties of our polar silicones, with a focus on improving the processability and functionality of thin films. The most promising polar silicone elastomers have also been investigated as dielectrics in actuators, sensors, energy harvesters, capacitive light-emitting devices and as electrolytes in solid-state Li-ion batteries, demonstrating their functionality.